by Industrial Print Magazine Staff

Software plays a pivotal role in the manufacture of a three-dimensional (3D) part. Many facets of the creation process benefit from software solutions, like product inventory management and designing a structure. It helps to cut down on time as well as expenses.

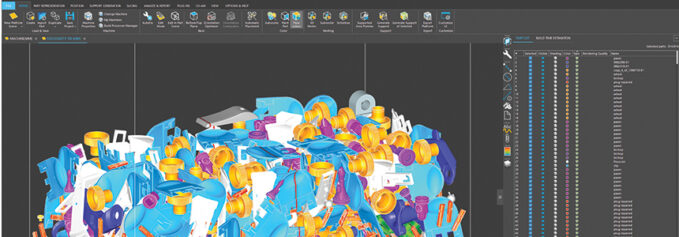

Above: Magics from Materialise centralizes every step of the AM process, from CAD import and data repair to part editing, labeling, nesting, support generation, slicing, and machine file output.

One tool used in additive manufacturing (AM) is build preparation software. According to Ajay Bharadwaj, head of software product development, Intech Additive Solutions Private Limited, build preparation software is essential to AM, as it handles all the critical functions for achieving high-quality prints.

“It manages everything from part orientation, support generation, and slicing to laser path planning and simulation. It also offers support-reduction options, enables cost analysis, facilitates connection to ERP systems, and helps determine process parameters based on geometry,” continues Bharadwaj.

A Necessity for Today

Build preparation software is a necessity in today’s AM world.

According to Egwin Bovyn, business line manager, Materialise Software, the way a build is prepared directly impacts cost, quality, and repeatability. “Build preparation software determines how well your machine performs, from orientation and support strategy to slicing, laser pathing, and thermal behavior. Intelligent build preparation software defines these parameters to optimize for machine and materials being used.”

Build preparation software is integral, especially as AM scales from prototyping to production printing.

“When transitioning AM from prototyping to production, there is a critical challenge—the CAD-to-print process isn’t plug and play. This is precisely where build preparation software becomes indispensable. Without robust data preparation software, scaling AM beyond prototyping would be incredibly difficult,” explains Bharadwaj.

Savings All Over

Build preparation software can save users money and time. It is also beneficial in avoiding wasting physical resources.

Production of an AM-built part generally leaves room for error. Bharadwaj says this is due to AM being a less mature build process, compared to say CNC machining. When using AM, issues can result like build failures—warping and re-coater interference, internal defects like porosity and lack of fusions, as well as inflated post-processing costs.

In the first year of metal 3D printing, Bovyn says customers typically scrap about 50 percent of their builds as they learn. Build preparation software can dramatically reduce iteration cycles. “Reducing iterations from six to two or even one is a huge time and cost savings. When dealing with expensive materials like titanium or Inconel, this translates to thousands of dollars saved per part development cycle,” continues Bovyn.

The aforementioned challenges are solved with build preparation software. “Such a product can serve as an invaluable tool, automating complex decisions and educating users, thereby enabling them to achieve right-first-time parts and significantly reducing overall operational costs,” says Bharadwaj.

The automated aspect of software, specifically build preparation software, is a time saver, agrees Bovyn. “Features such as nesting and labeling can be completed in minutes or even seconds instead of hours of manual work. This frees up skilled labor to focus on higher value tasks rather than repetitive preparation work.”

“Build preparation involves a sequence of steps that can be highly repetitive, especially if you’re printing a high volume of similar parts. Wherever there’s repetition, there’s an opportunity for automation,” agrees Safouan Itahriouan, AM senior application engineer EMEA, Qqton, in a blog post, How All-in-One AM Software Removes the Most Common Workflow Bottlenecks.

Another example of the 3D print process that benefits from automation is supports. “They are essential for printing overhangs or bridges, fixing the part to the build plate, and even removing heat. On the flip side, supports drive up costs due to additional material use as well as post-processing work. You can save on time and material if you optimize and automate support generation,” explains Itahriouan.

“With support templates, meta templates, and scripts you can apply the same strategy to similar builds. Even if a customer comes with an engineering order change a month after the initial print, you can apply all the same build preparation presets by replacing the old part version with the new one,” continues Itahriouan.

Options to Consider

Build preparation software is offered by either 3D printer manufacturers or third-party suppliers, through which the 3D printer manufacturer has vetted the solution to work with their device.

The advantage of working with third-party software is its vendor-agnostic characteristics, which enables a unified workflow across multiple machine brands and AM technologies, explains Bovyn. “This provides the flexibility necessary to adapt build preparation functionality to unique production requirements. This flexibility is critical in AM, especially given the huge variety of systems and technologies available in the market. AM requires far more than design files that a 3D printer can read. It requires a controlled, traceable, and multi-machine connected process,” adds Bovyn.

In either scenario, the ideal is “optimized performance achieved through tight integration with the 3D machine hardware,” admits Bharadwaj.

Intech Additive offers AMBuilder, a unique data preparation software. What sets it apart is its comprehensive suite of integrated plugins—covering part identification, simulation, support-less printing, and process parameter generation. AMBuilder is designed with the core goal of expanding metal AM by making the entire process intuitive for users. This deep integration, combined with seamless machine connectivity, empowers customers to achieve high-quality parts and significantly shorten their research and development cycles.

Materialise’s Magics software works for almost every AM system and materials from the OEM side, both polymer and metal printing. According to the company, Magics focuses on optimization, enabling new possibilities and providing advanced features including automation, simulation, labeling, support optimization, and traceability. It is suitable for everything from prototyping to full-scale production.

Magics centralizes every step of the AM process, from CAD import and data repair to part editing, labeling, nesting, support generation, slicing, and machine file output. For users who require traceability and process automation, Magics integrates seamlessly with Materialise Streamics or CO-AM platforms. Tools such as e-Stage for Metal+ enable automated support generation, saving time, material, and post-processing effort.

Oqton’s 3DXpert is a one-stop shop for AM. Streamline workflow, maximize efficiency, and avoid costly errors by completing all AM processes in the same software environment, including design for AM or DfAM, build preparation, simulation, and inspection. 3DXpert comes with a host of tools to automate repetition.

Siemens Digital Industries Software offers NX, with integrated build preparation tools that assist with placing, orienting, and supporting parts in the build tray in the most efficient manner possible. The build preparation solutions integrate into the NX CAD/CAM environment to enable changes to part designs that seamlessly ripple down to the manufacturing setup, without file conversions or costly build setup rework.

Print parts efficiently with complete control over part position and automated, efficient nesting within the build volume. Many builds require parts in a build tray to be serialized with unique markings or numbers. This can be accomplished within the NX AM build preparation system, where unique identifiers can be applied manually, programmatically, or via a spreadsheet interface. NX provides solutions for the automatic generation of support structures, as well as provides access to the full NX CAD solution for designing custom supports. Regardless of whether you are an AM novice or experienced user, this tight integration is an advantage when printing parts where final article quality is paramount.

Evolving, Yet Integrating

Build preparation software is an important tool in 3D printing. It helps save time and reduce costs, automating repetitive tasks and minimizing the chance for error and wasted materials.

According to Bovyn there is some concern that build preparation will disappear into CAD or OEM tools. “This is a misunderstanding. Integration is happening—and that’s a good thing. But integration doesn’t mean elimination. It means embedding intelligence into every stage of the workflow. Build preparation software isn’t going away—it’s evolving. It’s becoming smarter, more integrated, and more essential to making AM work in larger manufacturing environments.”

Sep2025, Industrial Print Magazine