by Industrial Print Magazine Staff

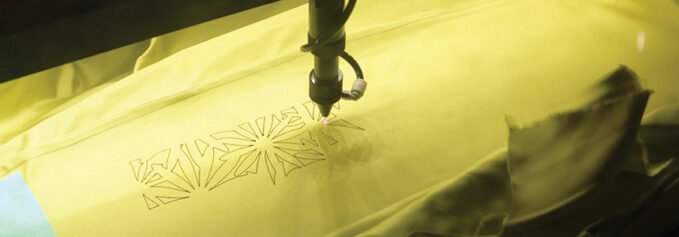

Laser cutters are well suited for finishing textile applications—from garments to soft signage. These devices offer non-contact, precision cutting, high-quality sealed edges, and high-speed micro-perforation. In addition, advanced camera technologies and automation tools are often incorporated.

Uli Kretzschmar, VP of SEI Laser sales, Matik, Inc., feels that laser technology is a proven solution for many markets and applications in printing and packaging along with several other areas like soft signage, technical textiles, fashion, and denim.

Versatility Attributes

Many benefits stand out when it comes to laser cutting technology for fabric applications, including precision cutting, sealing and welding capabilities, as well as maintenance considerations.

One clear benefit of laser cutting technologies is the ability to effectively process small, intricate patterns, point out Katlyn Dykhoff, marketing coordinator and Adam Voigt, sales representative, Kern Laser Systems.

This precision extends to accurately cutting textiles and fabrics like stretchable materials that are easily distorted. “Automated options on laser cutting systems can significantly shorten production time and minimize labor costs. Smart nesting makes maximum use of the designs on the material and perfectly controls waste management,” offers Daphne Mertens, marketing and communication, Summa.

“Automated software is beneficial as it identifies sublimated pieces with overhead cameras for continuous cutting,” adds Kimberly Daugherty, president, Advanced Color Solutions (ACS).

Tifanie Salazar, marketing manager, Yin USA Inc., seconds this sentiment. “A laser cutter is a great choice for businesses doing sublimation because a vision system can be added to automatically scan and cut around printed pattern pieces.”

“Fabric is alive, it moves, and when a tool touches it, it creates a wave that moves forward with the tool. This will create inaccuracy in the cut,” says Christina Lefebvre, area sales manager, North America, Matic. She explains that because laser cutting is a contact-less technology, the cutting tool is never in contact with the fabric, this reduces the risk of the fabric moving during the cutting process.

Mark Bibo, director, global field marketing, packaging, sign, and graphics, Lectra, agrees, since the laser uses light to cut, there is no mechanical contact with the material. “This results in more accurate cutting and better material utilization. More specifically, no over cuts, intricate shapes are now possible and can be nested closely together and quality parts can be cut very close to the material edges.”

Another popular advantage is a laser’s ability to process certain materials and seal or weld the edges so there is little to no fraying, add Dykhoff and Voigt.

Bibo explains that with laser cutters the edges are heat sealed. “This makes the overall sewing process more efficient.”

“The most notable advantage of laser cutting technology is that it seals the edges of the fabric it cuts, this allows a larger array of compatible fabrics without fear of them fraying,” agrees Lefebvre.

“Unlike a blade-based cutting tool, the laser can do two functions at once—cut the fabric and seal the edges,” says Beatrice Drury, marketing manager, Zund America, Inc. This ability eliminates the potential for fraying without having to add an extra finishing step. “It is ideal for woven polyester fabric, a material especially prone to fraying.”

“There is also no tool wearing with a laser, so no need to replace a knife or other cutting tool heads,” add Dykhoff and Voigt.

Kretzschmar feels that laser is a great option and complement to CNC cutters. “Due to the narrow focus of the laser beam, intricate cuts are possible. And due to its digital nature and precision control of the laser, it can not only be used for cutting but marking and etching to add another layer and dimension to the final product.”

“Laser cutting systems provide a strong link between printing businesses, fashion designers, and brands,” adheres Tong Li, Ph.D., CEO, AP Lazer. He suggests considering a laser machine as an added printer; replacing ink with a laser beam to cut/engrave fabric and many other fashion materials with great detail.

James Stanaway, director of marketing, Epilog Laser, praises laser’s versatility, especially “in terms of the textiles it cuts and marks. It is capable of cutting the most intricate patterns in leather, denim, lace, PVC-free heat transfer material, and twill. Settings can even be dialed in to kiss-cut multi-layer materials, such as a twill applique.”

There are both dedicated laser systems as well as digital cutting systems that offer laser options as a modular tool. Multi-process platforms shine in certain scenarios.

Depending on the specific type of textile you want to cut, a knife cutting machine may be preferred over a laser cutter. For example, natural fibers are known to perform better with knife-based systems. Mertens stresses that this doesn’t mean you cannot laser cut natural fibers, but they need to be tested thoroughly to find the best cutting solution.

“Non-woven, knitted fabrics, or any closed-loop textiles fray less, if at all,” adds Drury. For these applications, she suggests blade cutting tools are generally much less expensive to purchase and more productive to operate than the lower wattage lasers available for multi-purpose machines.

“The advantages of laser and simultaneous cutting and edge-sealing capabilities are also less desirable in production scenarios where sewing is a required function, or where the burning and melting involved in laser cutting results in discolored, brittle, or otherwise degraded edges.”

Dykhoff and Voigt admit that some materials react adversely to heat, for example the edges may brown slightly or melt some and create a small ridge on the edge that may not be pleasing to manufacturers. “With other cutting machines layering is usually an option, however with lasers there are times layering doesn’t give the desired outcome, though increased cutting speeds sometimes make up the difference. Lasers also are not capable of making channel or V-cuts in the fabric, and some lasers do not have the capabilities for five-axis cutting.”

Li adds that lasers cannot cut PVC or other toxic materials that generate harmful fumes, erode machine parts, and cause danger to humans.

Bibo agrees, noting that in his opinion, the biggest limitation with laser cutting is the material being cut should not contain PVC. “The material will cut fine, but gasses emitted when laser cutting PVC should be avoided.”

Cutting several layers at once can also be seen as a challenge when it comes to laser cutters. “This is due to the buildup of heat and the increased time to process, but lasers are better suited for detail and accuracy. Yes, high-quality lasers can cut multiple pieces at one time to maximize production efficiency, however, it is important to note that textiles are very diverse in composition and are made of natural or chemical fibers, so they must be processed appropriately. Parameters vary depending on the types of textiles used, thickness, and the number of layers. It’s important to have an understanding of the platform and configuration of your laser cutter,” suggests David Stevens, technical development manager, Trotec Laser.

Overcoming Hurdles

Laser cutting is a disruptive, fully digital technology that supports a fast growing and diversifying market with many new niches and applications. “New, high-tech and high-performance materials are designed and developed requiring new solutions in terms of functionality and significant added value. Converters have to get out of their comfort zone to meet those challenging market requirements,” says Kretzschmar.

To make sure the fabric does not warp or stretch, effective and efficient material handling features on the machine are key. Mertens says this is especially true when cutting sportswear or banners, a clean accurate cut is everything for the customer.

“Certain materials can have brown/burned edges from the laser cuts. If this edge is sewn into your product, then it won’t matter. If your cutting edges need to be clean for the integrity of your product, have your material tested on a laser cutter first,” recommends Salazar.

Return on investment should be considered with that cost, says Bibo. “If automating your cutting room is a hurdle, there are solutions that will ensure quality production.”

In addition to cost, Dykhoff and Voigt feel lack of education is another challenge. “Lasers are a newer technology and there are still many unknowns in terms of their benefits in certain manufacturing processes,” they note. “Lasers are being tried out in new applications every year and textiles is a relatively new market for them. People are still learning about the benefits of lasers for textiles, and for many manufacturers the change or standard, time-tested cutting options is a big decision that needs to allow time for proper research—as it should. So, the combination of not knowing they are an option, and the longer decision-making process is why we believe lasers have been slow to move into that market, though the number of lasers in textiles has been growing over the last few years.”

Li says the term laser cutter is a little misleading because solutions like AP Lazer’s CO2 laser machines can cut and engrave at the same time. “Engraving and cutting presents high potential in textile, because the finished product provides an emotional link to the consumer.”

“People often assume that laser cutters are difficult to program and use, but that couldn’t be farther from the truth,” stresses Stanaway. He says Epilog systems work similarly to printers.

Users insert the textile in the laser bed, import cutting patterns/shapes, and then send the job to the laser. The laser beam follows the designated cut lines determined by the operator. “While the laser itself is plug and play, some users find learning the graphic design software more challenging,” says Stanaway.

For dedicated laser systems, Drury says the biggest hurdle is the lack of versatility in terms of materials and applications that make sense for laser cutting.

Changes and Addressing Them

With labor shortages at an all-time high, no matter whether it is a knife or a laser cutter doing the job, automation is essential on the production floor. This is poised to continue well into the future.

While the folks at Autometrix only build knife cutters and not laser units, Jonathan Palmer, CEO, Autometrix, comments on the benefits of textile cutting at simply an automated versus manual level. “We have seen a consistent increase in interest over the last couple of years, and even with a consistent message of a recession confronting us each day, interest in cutting room automation isn’t slowing.”

Reasons why, well first off—it’s much faster than a hand cutter. “If a company has a single person cutting by hand full time, giving them the tools to increase their output by ten times allows their labor hours to be spent on something more valuable to the company as a whole. Second, everyone has seen major interruptions in their workforce, almost all because of pandemic-related sick leave for them or for their families. Bringing in the right cutting automation and software can take a normally highly skilled task and make it easier to train multiple people and still achieve the same results,” adds Palmer.

Laser Cutting for Textiles

When it comes to cutting textiles, lasers offer precision along with the ability to seal edges of media to avoid fraying. When it is time to select a cutting system, these tools are excellent for fabric environments.

Visit industrialprintmagazine.com/webinars to view a webinar on the topic.

Oct2022, Industrial Print Magazine