by Melissa Donovan

Corrugated printers and box plants that utilize digital printing in house benefit from the software that comes with it, particularly the data analytics and reporting pulled on a daily basis. Taking advantage of this information can help grow a business and maintain an efficient production floor.

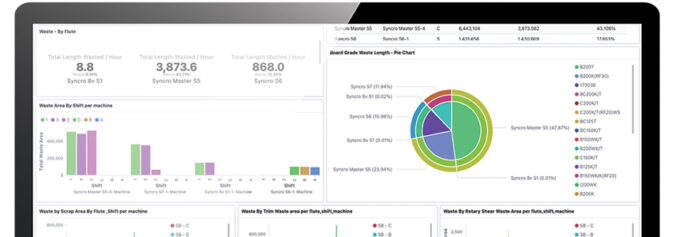

Above: Print ePS plays a critical role in ensuring the entire production workflow—from order entry to shipping—runs efficiently.

Technology in Use

There are many benefits to using automation software in digital corrugated board printing environments. One of which is the various data and reporting features that many workflows come equipped with, or if not built into the program, can integrate with a third-party solution.

Corrugated sheet plants and box plants rely on data and reporting features found in their current software solutions to drive smarter and faster decision making on the plant floor, according to Craig Tait, chief product officer, eProductivity Software (ePS).

“They’re using real-time production data to monitor quality, track waste, optimize ink consumption, and ensure jobs run on time and within spec. Many plants also integrate converting data with upstream scheduling and ERP systems to align converting production with order management and capacity planning. This helps teams proactively identify bottlenecks, adjust to last-minute changes, and improve overall equipment effectiveness,” explains Tait.

Matt Crawford, president/CEO, Onyx Graphics, Inc., says reporting tools also enable box plants and corrugated printers to run smarter and faster—in addition to becoming more profitable.

Modern print software with data and reporting features allow users to track jobs in real time, monitor ink and material usage, maintain consistent quality, schedule smarter, and measure performance, lists Crawford.

“Business owners can clearly see how printers and staff perform and where improvements can be made. Having data from past jobs makes it easier to plan production days and avoid last-minute delays,” continues Crawford.

Benefits to Consider

Integrated workflows reduce costs and increase uptime. The tools integrated throughout the system offer these two major advantages and more depending on the part of the process they are involved with. Data and reporting features offer significant benefits.

Automation features in software offer real-world business advantages. “Automation means less time setting up files, more time printing, and fewer operator mistakes,” says Crawford.

Utilizing data and reporting features is essential to making better decisions about print operations. “Data helps you understand which jobs are profitable, which machines are underperforming, and where to focus improvements,” shares Crawford.

“Data and reporting features offer better visibility across the production process, enabling faster troubleshooting and reducing downtime. They help identify trends in converting defects, enable consistent repeatability and quality control, and provide actionable insights for ongoing improvement. From a business perspective, they support more accurate job costing, drive down waste, and enhance customer satisfaction by ensuring print consistency and delivery performance,” explains Tait.

Adoption Push

While most production facilities have implemented software solutions that include data and reporting features, many are not using them to full capacity. Accelerating adoption in this space is a must.

“The reality is that many plants still operate in silos with a patchwork of legacy systems. If data and reporting tools can work with what’s already in place and deliver immediate insights without a steep learning curve, adoption increases dramatically,” admits Tait.

Vendors as well as industry leaders need to enhance software technology with a focus on interoperability, ease of integration, and user-friendly dashboards, lists Tait.

Crawford agrees. To help more companies take advantage of software solutions like these, systems need to be designed to easily connect to other systems, be simple to use, and work well with hardware. “Clean, easy-to-use dashboards help teams see what matters most without needing technical training and when software is designed to work with printers, finishers, and cutters right out of the box, adoption is faster and smoother.”

Education is also important. This includes success stories that “showcase tangible return on investment (ROI) from automation and reporting, which can help justify investment internally,” acknowledges Tait.

Showing ROI is how shops will truly understand the benefits, and then adopt the software. “Many shops save money and increase output by reducing errors and waste—real numbers help show the value,” says Crawford.

Insightful Operation

Data and reporting features in workflow software are useful tools that provide corrugated printers and box plants with insight into their production operations. Using the information that comes from these features allows shops to run more efficiently and achieve a faster ROI.

Oct2025, Industrial Print Magazine