by Industrial Print Magazine Staff

For over 25 years, Gentle Giant Studios has provided creative services to consumer products, fine art, gaming, visual effects, and experimental entertainment industries. It relies on three-dimensional (3D) scanning, modeling, and 3D printing to design and bring to life film props, toys and collectables, and much more.

Based in Burbank, CA, its 3D printing services are possible thanks to its 3D Systems ProX 950, ProJet MJP 2500, and iPro 8000 printers.

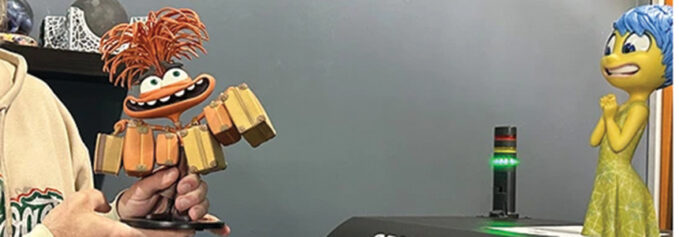

Above: Magics from Materialise is used for data and build preparation at Gentle Giant Studios.

Introducing a New Solution

Of course, hardware is only as good as the software that powers it. Jason Lopes, CTO, Gentle Giant Studios, joined the company in 2023. He immediately recognized the need for a revamp in how the company processes its 3D builds.

“When I joined, the team used generic build preparation software for automatic fixing. This software can technically make files printable, but it lacks the capability to help people learn. To get the best results, you need to learn quality modeling techniques before relying on build preparation software. Software with such basic functions doesn’t enable this type of development.”

Lopes introduced the Gentle Giant Studios team to Materialise’s Magics data and build preparation software. The solution is designed to help users gain control over their processes, automate repetitive tasks, and increase print success rates.

“Magics has always been my weapon of choice. In Magics, I can check for errors, modify parts to make them printable, complete Boolean operations—that’s huge in my world. But beyond that, I can make the business side of things simpler. For example, by estimating the costs of projects myself before sending them out,” says Lopes.

Magics keeps pace with the larger-than-life items Gentle Giant Studios is commonly asked to print. Not only are the final physical items large, the files themselves are complex.

“We don’t feel limitations when processing operations. You always get a real-time update on Magics’ progress. Years ago, I never would have thought it was possible. But with Magics, we have a program that keeps up with us,” shares Lopes.

Complex files also mean working with a software program that can streamline the process and eliminate any confusion. “We have many different workflows to keep track of. Some parts go to our model shop for cleanup to be a master pattern for casting. Some go to be painted. So you can imagine the type of instructions that need to accompany the parts. That’s where Magics’ reporting function comes in handy. Every department knows exactly what’s coming to them, what they need to do, and where the part needs to go next. It works very well,” admits Lopes.

Positive Outcome

Since Gentle Giant Studios implemented Magics, its found that compared to prior software, data and build preparation is 65 percent faster. With these improvements, the company frees up time once wasted on the software processing files and instead takes on more projects by expanding its customer base.

Sep2025, Industrial Print Magazine